Difference between revisions of "IntlVac NanoQuest 1 IBE"

Jump to navigation

Jump to search

| (19 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | [[Category:Etch]] | + | [[Category:Etch]][[Category:Equipment]] |

{{EquipmentInfo | {{EquipmentInfo | ||

| name = IntlVac Nanoquest 1 | | name = IntlVac Nanoquest 1 | ||

| Tool_Name = IntlVac IBE | | Tool_Name = IntlVac IBE | ||

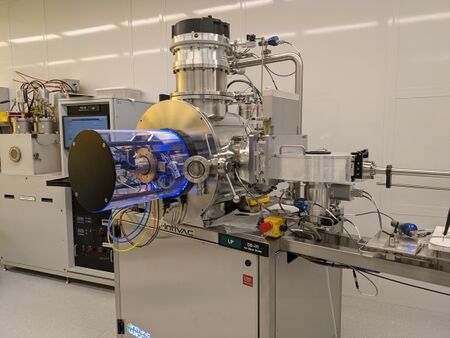

| − | | image = [[]] | + | | image = [[Image:IBE.jpg|450px]] |

| imagecaption = | | imagecaption = | ||

| Instrument_Type = Etch | | Instrument_Type = Etch | ||

| − | | Staff_Manager = [[ | + | | Staff_Manager = [[David Barth | David Barth]] |

| Lab_Location = Bay 2 | | Lab_Location = Bay 2 | ||

| Tool_Manufacturer = IntlVac | | Tool_Manufacturer = IntlVac | ||

| Line 13: | Line 13: | ||

| NEMO_Designation = DE-01 | | NEMO_Designation = DE-01 | ||

| Lab_Phone = 215-898-9748 | | Lab_Phone = 215-898-9748 | ||

| − | | SOP Link = [ | + | | SOP Link = [[Media:DE01_SOP.pdf|SOP]] |

}} | }} | ||

== Description == | == Description == | ||

| − | NanoQuest 1 is an ion miller connected to Ar gas and capable of | + | NanoQuest 1 is an ion miller connected to Ar gas and capable of etching small mm-scale samples up to full 4" wafers. The tool is equipped with a secondary ion mass spectroscopy (SIMS) unit and is capable of etching with manual endpoint detection. The stage has a tilt motor that allows for etch angles between 0 (directly facing the beam) and 90 degrees (parallel to the beam). |

| − | The tool in QNF is connected to Ar gas and can etch samples up to 4" | + | The tool in QNF is connected to Ar gas and can etch samples up to 4" wafers. |

Available beam voltages are: 300 V, 400 V, 450 V, and 500 V | Available beam voltages are: 300 V, 400 V, 450 V, and 500 V | ||

===== Applications ===== | ===== Applications ===== | ||

* Ion milling | * Ion milling | ||

| − | |||

| − | |||

| − | |||

| − | |||

== Standard Process Information == | == Standard Process Information == | ||

| Line 35: | Line 31: | ||

! Material || Voltage [V] || tilt [degree] || Etch Rate [nm/min] | ! Material || Voltage [V] || tilt [degree] || Etch Rate [nm/min] | ||

|- | |- | ||

| + | | [[ Cambridge Nanotech S200 ALD | ''' Al<sub>2</sub>O<sub>3<sub>''']] || 400 || 45 || 21 | ||

| + | |- | ||

| [[ Oxford PlasmaLab 100 PECVD | ''' SiO<sub>2<sub>''']] || 300 || 0 || 15 | | [[ Oxford PlasmaLab 100 PECVD | ''' SiO<sub>2<sub>''']] || 300 || 0 || 15 | ||

|- | |- | ||

| [[ Oxford PlasmaLab 100 PECVD | ''' SiO<sub>2<sub>''']] || 500 || 0 || 40 | | [[ Oxford PlasmaLab 100 PECVD | ''' SiO<sub>2<sub>''']] || 500 || 0 || 40 | ||

| − | |||

| − | |||

|} | |} | ||

| Line 55: | Line 51: | ||

|- | |- | ||

| AlSc(.36)N || 500 || 45 || 50 | | AlSc(.36)N || 500 || 45 || 50 | ||

| + | |- | ||

| + | | HfO2 || 300 || 0 || 20 | ||

|- | |- | ||

| LiNbO3 || 500 || 0 || 40 | | LiNbO3 || 500 || 0 || 40 | ||

| Line 63: | Line 61: | ||

|} | |} | ||

| − | == | + | == SOP & Troubleshooting == |

| + | |||

| + | *Operation video | ||

| + | [https://www.youtube.com/watch?v=1GsWXfCUXUg manual loading/unloading operation video] | ||

| + | |||

| + | |||

| + | *SOP | ||

| + | <pdf height="800"> File:DE01_SOP.pdf</pdf> | ||

Latest revision as of 15:41, 25 July 2025

|

|

| Tool Name | IntlVac IBE |

|---|---|

| Instrument Type | Etch |

| Staff Manager | David Barth |

| Lab Location | Bay 2 |

| Tool Manufacturer | IntlVac |

| Tool Model | Nanoquest 1 |

| NEMO Designation | DE-01 |

| Nearest Phone | 215-898-9748 |

| SOP Link | SOP |

Description

NanoQuest 1 is an ion miller connected to Ar gas and capable of etching small mm-scale samples up to full 4" wafers. The tool is equipped with a secondary ion mass spectroscopy (SIMS) unit and is capable of etching with manual endpoint detection. The stage has a tilt motor that allows for etch angles between 0 (directly facing the beam) and 90 degrees (parallel to the beam).

The tool in QNF is connected to Ar gas and can etch samples up to 4" wafers. Available beam voltages are: 300 V, 400 V, 450 V, and 500 V

Applications

- Ion milling

Standard Process Information

| Material | Voltage [V] | tilt [degree] | Etch Rate [nm/min] |

|---|---|---|---|

| Al2O3 | 400 | 45 | 21 |

| SiO2 | 300 | 0 | 15 |

| SiO2 | 500 | 0 | 40 |

Process information from user community

| Material | Voltage [V] | tilt [degree] | Etch Rate [nm/min] |

|---|---|---|---|

| Al | 400 | 45 | 60 |

| Al | 500 | 45 | 100 |

| AlN | 500 | 45 | 52 |

| AlSc(.36)N | 500 | 45 | 50 |

| HfO2 | 300 | 0 | 20 |

| LiNbO3 | 500 | 0 | 40 |

| Pt | 500 | 45 | 20 |

| SiO2 | 500 | 45 | 78 |

SOP & Troubleshooting

- Operation video

manual loading/unloading operation video

- SOP