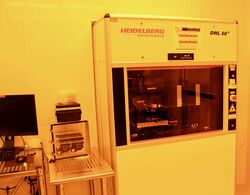

Heidelberg DWL 66+ Laser Writer

|

|

| Tool Name | Heidelberg DWL 66+ Laser Writer |

|---|---|

| Instrument Type | Lithography |

| Staff Manager | Ana Cohen |

| Lab Location | Bay 4 |

| Tool Manufacturer | Heidelberg |

| Tool Model | DWL 66+ |

| NEMO Designation | LW-01 |

| Nearest Phone | 8-9799 |

| SOP Link | SOP |

Description

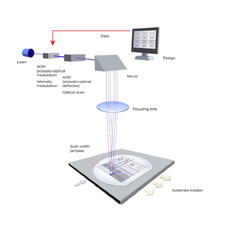

The fully automated DWL 66+ laser writing system has both binary (2D) and grayscale (2.5D) exposure capability.

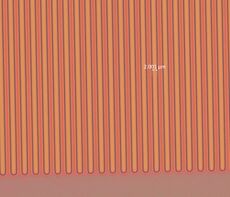

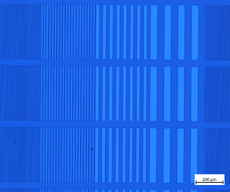

The pattern is broken into vertical stripes of ~500px with preset overlap. To write each stripe, the tool modulates and deflects the laser beam based on the provided pattern data while the stage moves along Y. This process repeats along the X direction until the pattern is complete.

Allowed Materials

Substrates

- Mask Plates -- available in the QNF Stockroom pre-coated with AZ1500 and IP3500

- 4" wafers

- Pieceparts > 20mm x 20mm (Starting Aug 2025, DMO system is recommended for small piece part direct write)

Resists -- must be compatible with h-line/ 405nm exposure (Laser exchanged in June 2023. Previous documentation may include 365nm capability.)

Processes

Writehead Selection

Pneumatic mode not currently recommended for dry etch and features under 3x listed minimum feature size due to focus issues -- working with Heidelberg service to address.

Last confirmed July 2025.

| Write Head | Optical Focus | Pneumatic Focus | Minimum Feature Size |

|---|---|---|---|

| 10mm | -70 | -100 | 2um |

| 2mm | +40 | -100 | 600nm |

| 40mm | N/A | -100 | 10um |

Exposure Parameters

Mask Plates

530nm resist thickness on chrome-coated soda lime, purchased from TELIC. Development in TMAH 0.26N for 60s. Values last confirmed July 2025.

AZ1500

Lower contrast resist - the default option for most applications

| Write Head | Filter(s) | Laser Power | Intensity |

|---|---|---|---|

| 10mm | 50% | 60 mW | 90 |

| 2mm | 12.5% + 25% | 60 mW | 80 |

| 40mm | NONE | 220 mW | 60 |

IP3500

Higher contrast resist - produces better corners and small pitch gratings

| Write Head | Filter(s) | Laser Power | Intensity |

|---|---|---|---|

| 10mm | NONE | 120 mW | 90 |

| 2mm | 12.5% + 50% | 60 mW | 80 |

Other direct writes

Resist on 4" silicon wafer, soft baked at 115C for 60s, development in TMAH 0.26N for 60s.

NOTE: Even if your resist is listed here, a dose test is always recommended to confirm optimal exposure parameters due to the variability of resist thickness, substrate reflectivity, and the ideal profile for subsequent processes.

| Resist | Thickness/Spin Speed | Write Head | Filter(s) | Laser Power | Intensity |

|---|---|---|---|---|---|

| S1805 | 0.5um (3krpm) | 10mm | 50% | 60 mW | 70 |

| S1818 | 2.2um (3krpm) | 10mm | NONE | 130 mW | 100 |