Difference between revisions of "TFS Quanta 600 FEG ESEM"

m (updated links to google drive) |

(i forget when i last saved this. fleshed out page with tables, troubleshooting info. details. organization. formatting. not complete yet.) |

||

| Line 12: | Line 12: | ||

| Tool_Model = Quanta 600F | | Tool_Model = Quanta 600F | ||

| NEMO_Designation = TFS Quanta 600 ESEM | | NEMO_Designation = TFS Quanta 600 ESEM | ||

| − | | Lab_Phone = | + | | Lab_Phone = N/A |

| SOP Link = [https://docs.google.com/document/d/1h893Du1kyHcroiIFzSnb-YEvJf7OluSYgo_xqFad3eg/edit?usp=sharing Quanta Reference Guide ] | | SOP Link = [https://docs.google.com/document/d/1h893Du1kyHcroiIFzSnb-YEvJf7OluSYgo_xqFad3eg/edit?usp=sharing Quanta Reference Guide ] | ||

}} | }} | ||

| Line 28: | Line 28: | ||

==== ''EDS with TEAM'' ==== | ==== ''EDS with TEAM'' ==== | ||

TEAM by EDAX is installed on the companion computer for [[EDS]] data collection and analysis. A guide for this program is available [https://docs.google.com/document/d/1V6E16ylrH1yMrVnW6dQYJnLbs4leSw3Cktv22yJHXpY/edit?usp=sharing here.] | TEAM by EDAX is installed on the companion computer for [[EDS]] data collection and analysis. A guide for this program is available [https://docs.google.com/document/d/1V6E16ylrH1yMrVnW6dQYJnLbs4leSw3Cktv22yJHXpY/edit?usp=sharing here.] | ||

| + | |||

| + | == User Responsibilities == | ||

| + | === Training === | ||

| + | |||

| + | Request training through [https://nemo.nano.upenn.edu/training/requests/ NEMO]. New users will complete at least two (2) training sessions with staff and demonstrate safe and competent operation of the tool to receive independent access (Prime time only: 9-5 weekdays.) | ||

| + | * Staff may require (or users may request) additional training before access is granted, or after initial training. | ||

| + | * Additional training for advanced techniques available upon request. | ||

| + | * 24/7 access may be granted at staff's discretion after completing at least 4 hours of independent use on the tool without incident. | ||

| + | * Staff may require refresher trainings after a period of disuse or after incidents. | ||

| + | |||

| + | === General Expectations === | ||

| + | * Reserve the tool through [https://nemo.nano.upenn.edu/calendar/ NEMO], then log in when you start and log out when finished. This enables the control PC monitor. | ||

| + | * Report problems through [https://nemo.nano.upenn.edu/tool_control/ NEMO]. | ||

| + | |||

| + | === Specimen Handling === | ||

| + | * Always wear gloves when handling anything that goes inside the SEM, including but not limited to: specimens, stubs, sample holders, and detectors. | ||

| + | * Do not overtighten set screws or remove them, unless necessary. | ||

| + | * Ensure samples are secure on their stubs or holders, especially powder or particulate specimens: particles that become loose inside the chamber may damage equipment. | ||

| + | === Sample and Detector Loading === | ||

| + | * Use an appropriate sample holder or stub. | ||

| + | * Check that the stage (x,y) is close to (0,0) when raising the stage. | ||

| + | * If the stage tilt is not at 0 when vented, or if the stage looks tilted, contact staff for assistance. | ||

| + | * Do not overtighten set screws or remove them. | ||

| + | * Carefully handle an additional detectors by the widest part and mind the pole piece when loading them into the chamber. Check the vacuum selection to ensure the detector is properly loaded. | ||

| + | |||

| + | === Data Management === | ||

| + | * Images are stored on the support computer under the left side of the main console. It is the middle of the three computers, connected to the rightmost monitor. | ||

| + | * Use a flash drive to transfer your images. | ||

| + | * Images are periodically deleted when the drive has too little free space (every few months.) Be sure to transfer your data in a timely manner. | ||

| + | * Respect other users if they are operating the SEM when you come to retrieve your images. | ||

| + | |||

| + | == Troubleshooting Tips == | ||

| + | ''See the SEM Troubleshooting section for more detailed information.'' | ||

| + | |||

| + | If the program stops responding, wait. Asking it to do more will take longer and may crash the program. Recommendation: turn the magnification knob when you suspect the program is frozen, then touch nothing else until it unfreezes. You will know it is ready when you see the magnification change. | ||

| + | |||

| + | To improve image quality, you may need to change one or multiple settings. | ||

| + | |||

| + | {| class = "wikitable" | ||

| + | |+ Troubleshooting Settings | ||

| + | |- | ||

| + | ! Setting !! Range !! Notes | ||

| + | |- | ||

| + | | Voltage* || 0.5 kV - 30 kV || Recommended range: 2 kV - 30 kV.</br>Low voltages are better for imaging surface detail and preventing specimen damage or charging in semi- to non-conductive specimens. </br> High voltages may yield better resolution, better material contrast, and are more suitable for longer working distances and analytical techniques such as EDS.</br>In low vacuum mode, the voltage and pressure are correlated for optimal charge compensation (see below.) | ||

| + | |- | ||

| + | | Pressure || High Vacuum: approx. 6x10-4 Pa</br>Low Vacuum: 0.1 - 1.5 torr</br>ESEM: 0.1 - 30 torr|| (add later) | ||

| + | |- | ||

| + | | Spot size* || 1 - 7 (arbitrary,) half step increments|| (add later) | ||

| + | |- | ||

| + | | Scan Speed || 50 ns - 1 ms || Fast scan speeds are useful for navigating the specimen, adjusting lens align, and changing the magnification. Slow speeds are useful for fine focusing, stigmator alignment, adjusting brightness and contrast/enhance before final image capture. | ||

| + | |- | ||

| + | | Image Size || 512x442</br>1024x884</br>2048x1768</br>4096x3536 || Doubling the image size results in a 4X increase in scan time. Larger image size enables digital zoom post-imaging to see smaller details within a larger field of view, and a larger file size. | ||

| + | |} | ||

| + | * ''Changing these settings will require some realignment of the beam'' | ||

| + | |||

| + | === Low Vacuum Troubleshooting === | ||

| + | In Low Vacuum mode, the pressure affects the resolution and charging, and is related to the voltage. | ||

| + | * Use the lowest voltage that yields a stable (not charging) image: | ||

| + | ** Set the pressure to 0.38 torr. | ||

| + | ** Adjust the voltage to optimize clarity of desired details (e.g. low voltage for surface detail.) | ||

| + | ** If the image is charging, increase the pressure. | ||

| + | ** You may also try decreasing the spot size. | ||

| + | * If a sample is charging, try increasing the pressure or decreasing the voltage. | ||

| + | * If the image is blurry after alignment, try decreasing the pressure. | ||

| + | * If the image is blurry after increasing the pressure to reduce charging, increase the voltage. | ||

| + | * In general, higher voltages tend to need higher pressures to compensate for charging. | ||

Revision as of 16:18, 28 March 2025

|

|

| Tool Name | Quanta |

|---|---|

| Instrument Type | ESEM |

| Staff Manager | Jamie Ford, Nicole Bohn |

| Lab Location | 004 |

| Tool Manufacturer | Thermo Fisher Scientific (Formerly FEI) |

| Tool Model | Quanta 600F |

| NEMO Designation | TFS Quanta 600 ESEM |

| Lab Phone | N/A |

| SOP Link | Quanta Reference Guide |

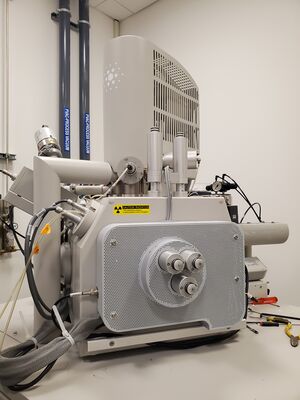

Overview

Description

The Quanta 600 FEG Mark II Environmental Scanning Electron Microscope achieves 1.5 nm resolution in ESEM mode and can be operated under a range of gaseous environments from 6 x 10-4 Pa to ~1000 Pa. It is equipped with a special wet STEM detector that is ideal for the imaging of nanoparticles in biological systems. This system is our platform for in-situ electron microscopy development with heating and cooling stages allowing imaging from 20-1000°C, dual Kleindiek nano-manipulators with a micro-droplet injection system for electrical and mechanical measurements, and gas injection systems for platinum and gold e-beam deposition.

Capabilities

The Quanta SEM is equipped with a unique array of accessories to enable the combination of high-resolution imaging and nanoscale manipulation allowing for powerful in-situ experiments involving controlled stimuli and correlated response. An EDAX Energy Dispersive x-ray spectrometer (EDS) allows for chemical characterization via spectra, element mapping, or phase mapping, and an electron backscatter diffraction detector (EBSD) is available for characterization of crystallographic structures.

In-Situ Applications

In-situ capabilities include: nanoscale manipulation of specimen or probe, access to the large sample volume by fluids, gases, electrical, optical and mechanical probes; detection of sample response to such probes, including the electron beam itself; and the temperature dependences of all these phenomena.

EDS with TEAM

TEAM by EDAX is installed on the companion computer for EDS data collection and analysis. A guide for this program is available here.

User Responsibilities

Training

Request training through NEMO. New users will complete at least two (2) training sessions with staff and demonstrate safe and competent operation of the tool to receive independent access (Prime time only: 9-5 weekdays.)

- Staff may require (or users may request) additional training before access is granted, or after initial training.

- Additional training for advanced techniques available upon request.

- 24/7 access may be granted at staff's discretion after completing at least 4 hours of independent use on the tool without incident.

- Staff may require refresher trainings after a period of disuse or after incidents.

General Expectations

- Reserve the tool through NEMO, then log in when you start and log out when finished. This enables the control PC monitor.

- Report problems through NEMO.

Specimen Handling

- Always wear gloves when handling anything that goes inside the SEM, including but not limited to: specimens, stubs, sample holders, and detectors.

- Do not overtighten set screws or remove them, unless necessary.

- Ensure samples are secure on their stubs or holders, especially powder or particulate specimens: particles that become loose inside the chamber may damage equipment.

Sample and Detector Loading

- Use an appropriate sample holder or stub.

- Check that the stage (x,y) is close to (0,0) when raising the stage.

- If the stage tilt is not at 0 when vented, or if the stage looks tilted, contact staff for assistance.

- Do not overtighten set screws or remove them.

- Carefully handle an additional detectors by the widest part and mind the pole piece when loading them into the chamber. Check the vacuum selection to ensure the detector is properly loaded.

Data Management

- Images are stored on the support computer under the left side of the main console. It is the middle of the three computers, connected to the rightmost monitor.

- Use a flash drive to transfer your images.

- Images are periodically deleted when the drive has too little free space (every few months.) Be sure to transfer your data in a timely manner.

- Respect other users if they are operating the SEM when you come to retrieve your images.

Troubleshooting Tips

See the SEM Troubleshooting section for more detailed information.

If the program stops responding, wait. Asking it to do more will take longer and may crash the program. Recommendation: turn the magnification knob when you suspect the program is frozen, then touch nothing else until it unfreezes. You will know it is ready when you see the magnification change.

To improve image quality, you may need to change one or multiple settings.

| Setting | Range | Notes |

|---|---|---|

| Voltage* | 0.5 kV - 30 kV | Recommended range: 2 kV - 30 kV. Low voltages are better for imaging surface detail and preventing specimen damage or charging in semi- to non-conductive specimens. High voltages may yield better resolution, better material contrast, and are more suitable for longer working distances and analytical techniques such as EDS. In low vacuum mode, the voltage and pressure are correlated for optimal charge compensation (see below.) |

| Pressure | High Vacuum: approx. 6x10-4 Pa Low Vacuum: 0.1 - 1.5 torr ESEM: 0.1 - 30 torr |

(add later) |

| Spot size* | 1 - 7 (arbitrary,) half step increments | (add later) |

| Scan Speed | 50 ns - 1 ms | Fast scan speeds are useful for navigating the specimen, adjusting lens align, and changing the magnification. Slow speeds are useful for fine focusing, stigmator alignment, adjusting brightness and contrast/enhance before final image capture. |

| Image Size | 512x442 1024x884 2048x1768 4096x3536 |

Doubling the image size results in a 4X increase in scan time. Larger image size enables digital zoom post-imaging to see smaller details within a larger field of view, and a larger file size. |

* Changing these settings will require some realignment of the beam

Low Vacuum Troubleshooting

In Low Vacuum mode, the pressure affects the resolution and charging, and is related to the voltage.

- Use the lowest voltage that yields a stable (not charging) image:

- Set the pressure to 0.38 torr.

- Adjust the voltage to optimize clarity of desired details (e.g. low voltage for surface detail.)

- If the image is charging, increase the pressure.

- You may also try decreasing the spot size.

- If a sample is charging, try increasing the pressure or decreasing the voltage.

- If the image is blurry after alignment, try decreasing the pressure.

- If the image is blurry after increasing the pressure to reduce charging, increase the voltage.

- In general, higher voltages tend to need higher pressures to compensate for charging.