Cambridge Nanotech S200 ALD

|

|

| Tool Name | Cambridge Nanotech S200 ALD |

|---|---|

| Instrument Type | Deposition |

| Staff Manager | Sam Azadi |

| Lab Location | Bay 1 |

| Tool Manufacturer | Ultratech/Cambridge |

| Tool Model | S200 |

| NEMO Designation | {{{NEMO_Designation}}} |

| Lab Phone | 215-898-9736 |

| SOP Link | QNF SOP |

Description

The QNF Savannah ALD is equipped with high-speed pneumatic pulse valves to enable our unique Exposure Mode™ for thin film deposition on ultra high aspect ratio substrates. This proven precision thin film coating methodology can be used to deposit conformal, uniform films on substrates with aspect ratios of greater than > 2000:1.

The QNF Savannah ALD is capable of holding substrates of different sizes (up to 200mm). The system is equipped with six precursor lines for deposition of Al2O3, HfO2, TiO2, and SiO2.

Applications

- Aluminum oxide deposition

- Silicon dioxide deposition

- Titanium oxide deposition

- Hafnium oxide deposition

- Deposition of other films can be made available upon request

Allowed material in ALD System

- Si, SixNy, SiO2, SOI

- Hard masks compatible with process temperature

Process Data

Standard Processes

- Water based depositions

| Material Name | Precursor 1 | Precursor 2 | Dep. temperature [C] | Carrier flow [sccm] | Dep. rate [A/cyc] | Date [MM/DD/YY] | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Name | Pulse time [s] | Wait time [s] | Name | Pulse time [s] | Wait time [s] | |||||

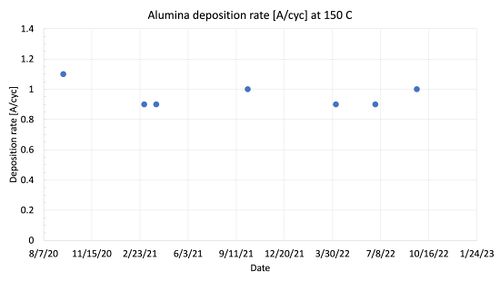

| Al2O3 | TMA | 0.015 | 5 | H2O | 0.015 | 5 | 245 | 20 | 1 | 12/16/22 |

| Al2O3 | TMA | 0.015 | 5 | H2O | 0.015 | 5 | 200 | 20 | 1 | 09/24/22 |

| Al2O3 | TMA | 0.015 | 5 | H2O | 0.015 | 5 | 150 | 20 | 0.9 | 12/14/22 |

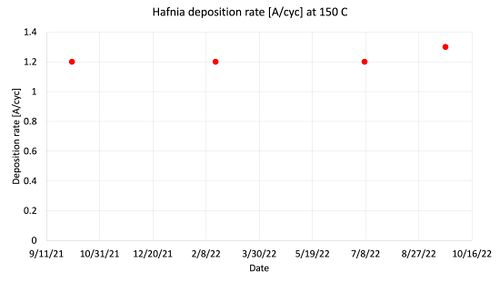

| HfO2 | TDMAHf | 0.15 | 8 | H2O | 0.015 | 5 | 200 | 20 | 1.3 | 09/24/22 |

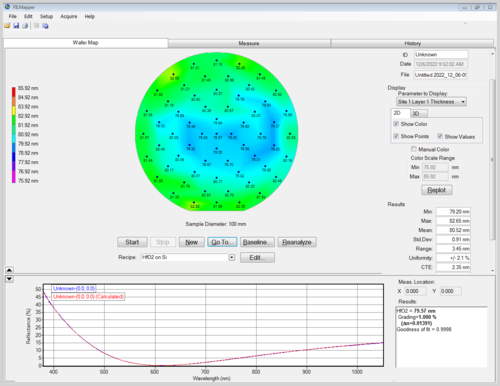

| HfO2 | TDMAHf | 0.4 | 8 | H2O | 0.015 | 8 | 150 | 20 | 1.3 | 12/06/22 |

| TiO2 | TDMATi | 0.4 | 10 | H2O | 0.015 | 5 | 250 | 20 | 0.4 | 05/02/22 |

| TiO2 | TDMATi | 0.3 | 10 | H2O | 0.015 | 10 | 150 | 20 | 0.5 | 01/04/23 |

- Ozone based depositions

| Material Name | Precursor 1 | Precursor 2 | Dep. temperature [C] | Carrier flow [sccm] | Dep. rate [A/cyc] | Date [MM/DD/YY] | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Name | Pulse time [s] | Wait time [s] : Stop Valve closed / open | Name | Pulse time [s] | Wait time [s] : Stop Valve closed / open | |||||

| SiO2 | BDEAS | 0.15 | 5 SV closed/ 8 SV open | O3 | 0.015 | 5 SV closed/ 8 SV open | 150 | 20 | 0.5 | 12/08/22 |

Deposition Rate Monitoring

- Deposition uniformity example

HfO2 film uniformity deposited on 12/06/2022, process details in the table above