Difference between revisions of "Oxford PlasmaLab 100 PECVD"

(Created page with "Category:Deposition {{EquipmentInfo | name = Cambridge Nanotech S200 ALD | Tool_Name = Cambridge Nanotech S200 ALD | image = 300px | imagecaption =...") |

|||

| (41 intermediate revisions by 4 users not shown) | |||

| Line 2: | Line 2: | ||

{{EquipmentInfo | {{EquipmentInfo | ||

| − | | name = | + | | name = Oxford PlasmaLab 100 PECVD |

| − | | Tool_Name = | + | | Tool_Name = Oxford PlasmaLab 100 PECVD |

| − | | image = [[Image: | + | | image = [[Image:CVD-01.jpeg|300px]] |

| imagecaption = | | imagecaption = | ||

| Instrument_Type = Deposition | | Instrument_Type = Deposition | ||

| − | | Staff_Manager = Sam Azadi | + | | Staff_Manager = [[Sam Azadi | Sam Azadi]] |

| − | | Lab_Location = Bay | + | | Lab_Location = Bay 1 |

| − | | Tool_Manufacturer = | + | | Tool_Manufacturer = Oxford |

| − | | Tool_Model = | + | | Tool_Model = PlasmaLab 100 |

| − | | | + | | NEMO_Designation = CVD-01 |

| − | | Lab_Phone = | + | | Lab_Phone = 215-898-9736 |

| − | | SOP Link = [https://repository.upenn.edu/scn_sop/ | + | | SOP Link = [https://repository.upenn.edu/scn_sop/5/ QNF SOP] |

}} | }} | ||

== Description == | == Description == | ||

| − | The QNF | + | The QNF Oxford Instruments PlasmaLab System 100 Plasma Enhanced Chemical Vapor Deposition (PECVD) tool is used to deposit a variety of thin-film materials at relatively modest temperatures on a variety of substrate materials. The tool utilizes an RF generator to deposit thin films at temperatures lower than traditional chemical vapor deposition systems. The tool operates between 150 and 350 C. |

| − | |||

===== Applications ===== | ===== Applications ===== | ||

| − | |||

* Silicon dioxide deposition | * Silicon dioxide deposition | ||

| − | * | + | * Silicon nitride deposition |

| − | * | + | * [[Amorphous silicon deposition | Amorphous silicon deposition]] |

| − | |||

| − | ===== Allowed material in | + | ===== Allowed material in PECVD System ===== |

| − | * Si, Si<sub>x</sub>N<sub>y</sub>, SiO<sub>2</sub>, SOI | + | * Si, Si<sub>x</sub>N<sub>y</sub>, SiO<sub>2</sub>, SOI, SiC, GaN |

| + | * Al, Pt, Cr, W, Mo, Ti | ||

* Hard masks compatible with process temperature | * Hard masks compatible with process temperature | ||

| + | |||

| + | ==== List of materials NOT allowed in the chamber ==== | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Name || symbol || Melting Point [C] | ||

| + | |- | ||

| + | | Bismuth || Bi || 271 | ||

| + | |- | ||

| + | | Cadmium || Cd || 321 | ||

| + | |- | ||

| + | | Carbon || C || Subl. | ||

| + | |- | ||

| + | | Gallium || Ga || 30 | ||

| + | |- | ||

| + | | Gold || Au || 1062 | ||

| + | |- | ||

| + | | Indium || In || 157 | ||

| + | |- | ||

| + | | Lead || Pb || 328 | ||

| + | |- | ||

| + | | Lithium || Li || 179 | ||

| + | |- | ||

| + | | Selenium || Se || 217 | ||

| + | |- | ||

| + | | Sulfur || S || 115 | ||

| + | |- | ||

| + | | Tellurium || Te || 452 | ||

| + | |- | ||

| + | | Thallium || Tl || 302 | ||

| + | |- | ||

| + | | Tin || Sn || 232 | ||

| + | |- | ||

| + | | Zinc || Zn || 419 | ||

| + | |} | ||

| + | |||

| + | == Process information == | ||

| + | |||

| + | |||

| + | === Standard process data - Table temperature fixed at 350 C === | ||

| + | * SiO2 on 01/09/2024 | ||

| + | |||

| + | Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section | ||

| + | |||

| + | Recipe name on the tool: Test-SiO2 | ||

| + | |||

| + | Deposition rate: ~ 291 nm/min ± 5 nm/min | ||

| + | |||

| + | |||

| + | |||

| + | * SiNx on 07/29/2024 | ||

| + | |||

| + | Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section | ||

| + | |||

| + | Recipe name on the tool: Test-SiNx deposition | ||

| + | |||

| + | Deposition rate: ~ 46 nm/min ± 2 nm/min | ||

| + | |||

| + | |||

| + | |||

| + | * a-Si on 01/09/2024 | ||

| + | |||

| + | Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section | ||

| + | |||

| + | Recipe name on the tool: a-Si | ||

| + | |||

| + | Deposition rate: ~ 60 nm/min ± 5 nm/min | ||

| + | |||

| + | |||

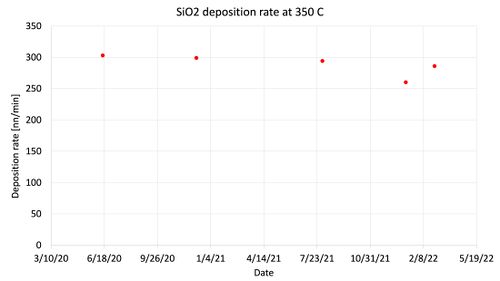

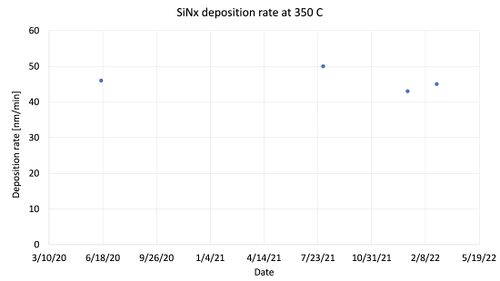

| + | ==== Deposition Rate Monitoring ==== | ||

| + | [[Image:Sio2 dep on cvd-01.jpg|left|500px]] [[Image:Sinx dep rate on cvd-01.jpg|center|500px]] | ||

| + | |||

| + | |||

| + | === Special process data - adjustable table temperature === | ||

| + | * SiO2 | ||

| + | |||

| + | Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section - table temperature at 200 C | ||

| + | |||

| + | Recipe name on the tool: Test-SiO2 | ||

| + | |||

| + | Deposition rate: ~ 230 nm/min ± 2 nm/min | ||

== Resources == | == Resources == | ||

===== SOPs & Troubleshooting ===== | ===== SOPs & Troubleshooting ===== | ||

| − | * [https://repository.upenn.edu/scn_sop/ | + | * [https://repository.upenn.edu/scn_sop/5/ QNF SOP] |

| + | * [https://upenn.box.com/s/sglgbidfjpw36f6v50rzgcpll5yliloc/ PECVD Table Temp Tuning Procedure] | ||

| + | |||

| + | ===== Protocols and Reports ===== | ||

| + | * [https://repository.upenn.edu/scn_tooldata/34/ SiO<sub>2</sub> deposition process parameters] | ||

| + | * [https://repository.upenn.edu/scn_tooldata/35/ SiN<sub>x</sub> deposition process parameters] | ||

| + | * [https://repository.upenn.edu/scn_tooldata/43/ Optimization of a-Si deposition on Oxford PlasmaLab 100 PECVD using Taguchi L9 based DOE] | ||

Latest revision as of 13:41, 14 October 2024

|

|

| Tool Name | Oxford PlasmaLab 100 PECVD |

|---|---|

| Instrument Type | Deposition |

| Staff Manager | Sam Azadi |

| Lab Location | Bay 1 |

| Tool Manufacturer | Oxford |

| Tool Model | PlasmaLab 100 |

| NEMO Designation | CVD-01 |

| Lab Phone | 215-898-9736 |

| SOP Link | QNF SOP |

Description

The QNF Oxford Instruments PlasmaLab System 100 Plasma Enhanced Chemical Vapor Deposition (PECVD) tool is used to deposit a variety of thin-film materials at relatively modest temperatures on a variety of substrate materials. The tool utilizes an RF generator to deposit thin films at temperatures lower than traditional chemical vapor deposition systems. The tool operates between 150 and 350 C.

Applications

- Silicon dioxide deposition

- Silicon nitride deposition

- Amorphous silicon deposition

Allowed material in PECVD System

- Si, SixNy, SiO2, SOI, SiC, GaN

- Al, Pt, Cr, W, Mo, Ti

- Hard masks compatible with process temperature

List of materials NOT allowed in the chamber

| Name | symbol | Melting Point [C] |

|---|---|---|

| Bismuth | Bi | 271 |

| Cadmium | Cd | 321 |

| Carbon | C | Subl. |

| Gallium | Ga | 30 |

| Gold | Au | 1062 |

| Indium | In | 157 |

| Lead | Pb | 328 |

| Lithium | Li | 179 |

| Selenium | Se | 217 |

| Sulfur | S | 115 |

| Tellurium | Te | 452 |

| Thallium | Tl | 302 |

| Tin | Sn | 232 |

| Zinc | Zn | 419 |

Process information

Standard process data - Table temperature fixed at 350 C

- SiO2 on 01/09/2024

Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section

Recipe name on the tool: Test-SiO2

Deposition rate: ~ 291 nm/min ± 5 nm/min

- SiNx on 07/29/2024

Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section

Recipe name on the tool: Test-SiNx deposition

Deposition rate: ~ 46 nm/min ± 2 nm/min

- a-Si on 01/09/2024

Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section

Recipe name on the tool: a-Si

Deposition rate: ~ 60 nm/min ± 5 nm/min

Deposition Rate Monitoring

Special process data - adjustable table temperature

- SiO2

Recipe parameters: optimized process parameters are in the report under "Protocols and Reports" section - table temperature at 200 C

Recipe name on the tool: Test-SiO2

Deposition rate: ~ 230 nm/min ± 2 nm/min