Difference between revisions of "Heidelberg DWL 66+ Laser Writer"

| (29 intermediate revisions by 2 users not shown) | |||

| Line 7: | Line 7: | ||

| imagecaption = | | imagecaption = | ||

| Instrument_Type = Lithography | | Instrument_Type = Lithography | ||

| − | | Staff_Manager = | + | | Staff_Manager = [[Ana Cohen | Ana Cohen]] |

| − | | Lab_Location = Bay | + | | Lab_Location = Bay 4 |

| Tool_Manufacturer = Heidelberg | | Tool_Manufacturer = Heidelberg | ||

| Tool_Model = DWL 66+ | | Tool_Model = DWL 66+ | ||

| − | | | + | | NEMO_Designation = LW-01 |

| Lab_Phone = 8-9799 | | Lab_Phone = 8-9799 | ||

| − | | SOP Link = [https:// | + | | SOP Link = [https://nemo.nano.upenn.edu/media/tool_documents/lw-01-heidelberg-dwl66/LW-01_SOP_v02.pdf SOP] |

}} | }} | ||

== Description == | == Description == | ||

| − | The fully automated DWL 66+ laser writing system is located inside an environment chamber for stable environment of the system with controlled laminar airflow and temperature stability. The chamber is situated on a granite base with air cushions for vibration isolation. The optical system includes highly reflective mirrors and acousto-optic modulators for real-time beam correction. | + | The fully automated DWL 66+ laser writing system is located inside an environment chamber for stable environment of the system with controlled laminar airflow and temperature stability. The chamber is situated on a granite base with air cushions for vibration isolation. The optical system includes highly reflective mirrors and acousto-optic modulators for real-time beam correction. The laser is 405nm wavelength (h-line). |

'''Lens & Resolution''' | '''Lens & Resolution''' | ||

| Line 24: | Line 24: | ||

* 40 mm lens (pneumatic autofocus): 10 µm | * 40 mm lens (pneumatic autofocus): 10 µm | ||

| + | ===== Applications ===== | ||

| + | * [https://nemo.nano.upenn.edu/media/tool_documents/lw-01-heidelberg-dwl66/How_to_Make_a_Mask_At_QNF_v05.pdf Patterning of photomasks] | ||

| + | * Direct laser writing on substrates, from 6" wafers down to 10mm x 10mm pieces | ||

| − | ===== | + | ===== Allowed Materials ===== |

| − | * | + | * Mask Plates -- available in the [https://nemo.nano.upenn.edu/stockroom/ QNF Stockroom] pre-coated with AZ1500 and IP3500 |

| − | * | + | * Resists -- must be compatible with h-line exposure |

| + | ** [[Resists_at_QNF#QNF_Supplied_Standard_Photoresists | S1800 series]] | ||

| + | ** [[Resists_at_QNF#Miscellaneous | KL5300 series]] | ||

| + | ** [[Resists_at_QNF#Other_Resists | LOR]] | ||

== Processes == | == Processes == | ||

| − | The following exposure parameters may be used to expose photomasks. | + | The following exposure parameters may be used to expose photomasks. <em> </em> |

{| class="wikitable" style="vertical-align:bottom;" | {| class="wikitable" style="vertical-align:bottom;" | ||

|- | |- | ||

| Line 44: | Line 50: | ||

| AZ1500 | | AZ1500 | ||

| 10mm | | 10mm | ||

| + | | 25% | ||

| + | | 70 | ||

| 50% | | 50% | ||

| − | |||

| − | |||

| -30 | | -30 | ||

| 1 | | 1 | ||

| Line 53: | Line 59: | ||

| IP3500 | | IP3500 | ||

| 10mm | | 10mm | ||

| − | | | + | | NONE |

| − | | | + | | 70 |

| − | | | + | | 50% |

| -30 | | -30 | ||

| + | | 1 | ||

| + | | Pneumatic | ||

| + | |- | ||

| + | | AZ1500 | ||

| + | | 2mm | ||

| + | | 12.5%+25%+50% | ||

| + | | 60 | ||

| + | | 50% | ||

| + | | -15 | ||

| 1 | | 1 | ||

| Pneumatic | | Pneumatic | ||

| Line 62: | Line 77: | ||

| IP3500 | | IP3500 | ||

| 2mm | | 2mm | ||

| − | | | + | | 12.5%+25% |

| 60 | | 60 | ||

| − | | | + | | 50% |

| − | | - | + | | -15 |

| 1 | | 1 | ||

| Pneumatic | | Pneumatic | ||

| Line 71: | Line 86: | ||

| − | The following exposure parameters may be used to direct write into | + | The following exposure parameters may be used to direct write into S18xx resist on silicon (soft baked at 115C for 60s, development in TMAH 0.26N for 60s). For the optimum focus, please refer to the "AZ1500.txt" or "IP3500.txt" files for the optimum value to use. [May not be up-to-date. It is always a good idea to check your resist thickness and run a dose test to confirm optimal parameters.] |

{| class="wikitable" | {| class="wikitable" | ||

| Line 87: | Line 102: | ||

| 3000 | | 3000 | ||

| 10mm | | 10mm | ||

| − | | | + | | 12.5% |

| − | | | + | | 105 |

| 60% | | 60% | ||

| 1 | | 1 | ||

| Line 95: | Line 110: | ||

| S1805 | | S1805 | ||

| 3000 | | 3000 | ||

| + | | 2mm | ||

| + | | 1% & 50% | ||

| + | | TBD | ||

| + | | TBD | ||

| + | | 1 | ||

| + | | pneumatic | ||

| + | |- | ||

| + | | KL5315 | ||

| + | | 5000 | ||

| + | | 10mm | ||

| + | | 50% | ||

| + | | TBD | ||

| + | | TBD | ||

| + | | 1 | ||

| + | | pneumatic | ||

| + | |- | ||

| + | | KL5315 | ||

| + | | 5000 | ||

| 2mm | | 2mm | ||

| 1% | | 1% | ||

| − | | | + | | TBD |

| − | | | + | | TBD |

| 1 | | 1 | ||

| pneumatic | | pneumatic | ||

| Line 105: | Line 138: | ||

| 3000 | | 3000 | ||

| 10mm | | 10mm | ||

| − | | | + | | NONE |

| − | | | + | | 65 |

| − | | | + | | 60% |

| 1 | | 1 | ||

| pneumatic | | pneumatic | ||

| Line 114: | Line 147: | ||

| 3000 | | 3000 | ||

| 2mm | | 2mm | ||

| − | | 12.5% | + | | 12.5% & 25% |

| − | | | + | | TBD |

| − | | | + | | TBD |

| 1 | | 1 | ||

| pneumatic | | pneumatic | ||

|} | |} | ||

| + | |||

| + | |||

| + | |||

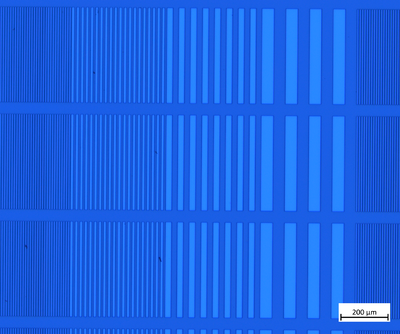

| + | [[File:LW-01 S1818Lines 25um Feb2024.png|400px|]] [[File:LW-01 S1818Lines 5um Feb2024.png|400px|]] | ||

| + | S1818 at 3000rpm (2.2um thickness) with 10mm writehead [Feb 2024] | ||

| + | 65mW, NO Filter, 70% intensity, + 20 focus | ||

| + | 5um, 10um, 25um, and 50um line widths after 60s TMAH 0.26N development | ||

== Resources == | == Resources == | ||

| + | |||

| + | * [https://nemo.nano.upenn.edu/media/tool_documents/lw-01-heidelberg-dwl66/How_to_Make_a_Mask_At_QNF_v05.pdf How to Make a Mask at QNF] | ||

| + | * [https://www.youtube.com/playlist?list=PLiihbHV9HgpWZikttBFUh2O8EGUsRu348 Videos - BEAMER Training for LW-01] | ||

===== SOPs & Troubleshooting ===== | ===== SOPs & Troubleshooting ===== | ||

| − | * [https:// | + | * [https://nemo.nano.upenn.edu/media/tool_documents/lw-01-heidelberg-dwl66/LW-01_SOP_v02.pdf SOP] |

| + | * [https://www.youtube.com/watch?v=q_mvEGSCEGI&list=PLiihbHV9HgpWAcmgdpMGBkejcBhEzoKJO Videos - LW-01 Tool Training] | ||

| + | * [https://drive.google.com/file/d/1MUMPdLl4GfXtmg3gJjdiPKbdiyCq-elM/view?usp=drive_link Video - Chuck Installation/Removal] | ||

Latest revision as of 18:41, 28 October 2024

|

|

| Tool Name | Heidelberg DWL 66+ Laser Writer |

|---|---|

| Instrument Type | Lithography |

| Staff Manager | Ana Cohen |

| Lab Location | Bay 4 |

| Tool Manufacturer | Heidelberg |

| Tool Model | DWL 66+ |

| NEMO Designation | LW-01 |

| Lab Phone | 8-9799 |

| SOP Link | SOP |

Description

The fully automated DWL 66+ laser writing system is located inside an environment chamber for stable environment of the system with controlled laminar airflow and temperature stability. The chamber is situated on a granite base with air cushions for vibration isolation. The optical system includes highly reflective mirrors and acousto-optic modulators for real-time beam correction. The laser is 405nm wavelength (h-line).

Lens & Resolution

- 2 mm lens (optical autofocus): 600 nm

- 10 mm lens (pneumatic autofocus): 2 µm

- 40 mm lens (pneumatic autofocus): 10 µm

Applications

- Patterning of photomasks

- Direct laser writing on substrates, from 6" wafers down to 10mm x 10mm pieces

Allowed Materials

- Mask Plates -- available in the QNF Stockroom pre-coated with AZ1500 and IP3500

- Resists -- must be compatible with h-line exposure

Processes

The following exposure parameters may be used to expose photomasks.

| Resist | Write Head | Filter(s) | Laser Power (mW) | Intensity | Focus | # of passes | Focus mode |

|---|---|---|---|---|---|---|---|

| AZ1500 | 10mm | 25% | 70 | 50% | -30 | 1 | Pneumatic |

| IP3500 | 10mm | NONE | 70 | 50% | -30 | 1 | Pneumatic |

| AZ1500 | 2mm | 12.5%+25%+50% | 60 | 50% | -15 | 1 | Pneumatic |

| IP3500 | 2mm | 12.5%+25% | 60 | 50% | -15 | 1 | Pneumatic |

The following exposure parameters may be used to direct write into S18xx resist on silicon (soft baked at 115C for 60s, development in TMAH 0.26N for 60s). For the optimum focus, please refer to the "AZ1500.txt" or "IP3500.txt" files for the optimum value to use. [May not be up-to-date. It is always a good idea to check your resist thickness and run a dose test to confirm optimal parameters.]

| Resist | Spin Speed (RPM) | Write Head | Filter(s) | Laser Power (mW) | Intensity | # passes | Focus mode |

|---|---|---|---|---|---|---|---|

| S1805 | 3000 | 10mm | 12.5% | 105 | 60% | 1 | pneumatic |

| S1805 | 3000 | 2mm | 1% & 50% | TBD | TBD | 1 | pneumatic |

| KL5315 | 5000 | 10mm | 50% | TBD | TBD | 1 | pneumatic |

| KL5315 | 5000 | 2mm | 1% | TBD | TBD | 1 | pneumatic |

| S1818 | 3000 | 10mm | NONE | 65 | 60% | 1 | pneumatic |

| S1818 | 3000 | 2mm | 12.5% & 25% | TBD | TBD | 1 | pneumatic |

S1818 at 3000rpm (2.2um thickness) with 10mm writehead [Feb 2024] 65mW, NO Filter, 70% intensity, + 20 focus 5um, 10um, 25um, and 50um line widths after 60s TMAH 0.26N development